Electroless Nickel Plating

Electroless Nickel Plating Capabilities for Prototype, Rack and Barrel Projects

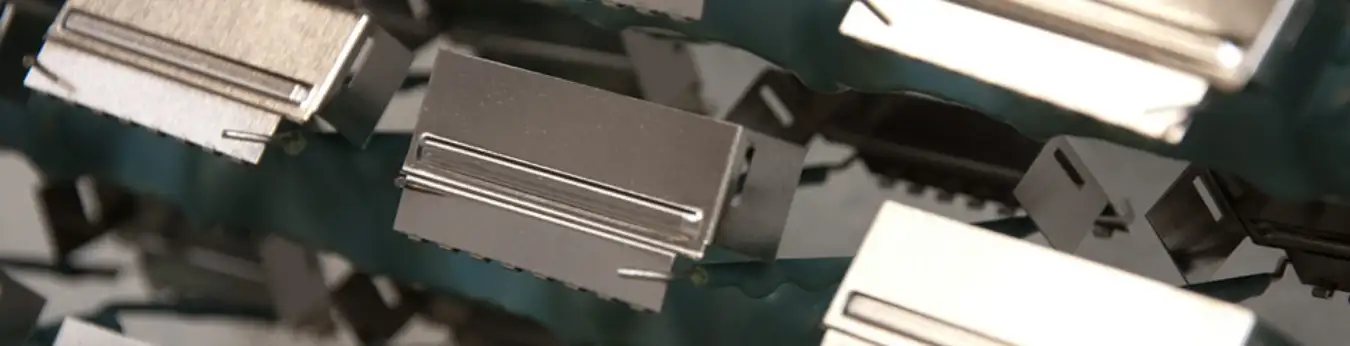

Electroless nickel plating can be expensive and a hard service to find, which is why Precision Plating in Chicago applies its mission of impeccable service to this difficult market. If your application requires nickel or copper finishing and tolerance is a main concern, consider electroless metal plating from Precision. The electroless plating process creates a finish far more uniformed than what is achieved through a standard electrolytic process. The uniform deposition of this finishing process and its ability to be applied over non-conductive surfaces, such as plastics, makes it a versatile solution.

Electroless Metal Plating offers a variety of advantages:

- Plating volume and thickness is adaptable

- Even surface coating

- Great for plating recesses and blind holes with uniformity

- Exceptional protection against corrosion

- No need for liquid lubricants

Electroless Metal Plating Capabilities

Electroless nickel finishing is the most common electroless metal process, and works well in products with an aluminum base material. Processing delicate products in electroless nickel is a large part of our business here at Precision and we work very closely as an approved supplier with a number of large defense contractors. Silver, tin, palladium and gold can also be applied through this finishing process.

When you need a project done right, leave it to the leaders at Precision. Our quality, service and process standards meet ISO/TS 16949:2009 standards. Whether it's copper, gold, silver, nickel, tin, or palladium, we have the right metal plating process to meet your needs. We offer this finish in each of the following segments of our capabilities: Prototype / Rack / Barrel