Metal Plating

Electroless Metal Plating Leaders: Precision Plating Company

Electroless metal plating can be expensive and hard to find. That is why Precision applies it's mission of impeccable service to this difficult market. Leave it to the leaders in electroplating and electroless metal plating - Precision Plating. Whether it's copper, gold, silver, nickel, tin, or palladium, we have the right metal plating process to meet your needs. We also give you options and technology in electroless metal plating techniques from a company whose quality, service and process meet the ISO/TS 16949:2009 standards. That's why it pays to use a reliable company like Precision Plating when the right electroless metal plating is critical to the success of your project.

Electroless Metal Plating to Fit Any Project Specification

If your application requires nickel or copper plating and tolerance is of a main concern, then try electroless plating. In the electroless plating process, electrons still flow between the redox couple in the bath. However, the process has no electrodes and therefore plates far more uniformly than a standard electrolytic process. Copper electroless plating is ideal for applications in the semiconductor industry. The uniform deposition of electroless finishing and its ability to be applied over non-conductive surfaces, such as plastics, makes it a versatile solution.

Why Precision Plating Company?

Located in Chicago, Illinois, Precision Plating Company draws upon nearly 900 years of metal plating experience to provide barrel, rack, selective and overall continuous reel to reel plating services. In addition to providing Impeccable Service and being a preferred supplier to worldwide semiconductor and global automotive industry leaders, quality and repeatability are assured through our ISO/TS 16949:2009 registered quality systems certification.

Quality Metal Plating Technologies to Direct Specifications and Project Needs

Continuous Reel to Reel Plating: With 40 years of experience in reel to reel finishing, you can depend on Precision for innovative solutions that other companies might say are impossible. Involving Precision in the design process with your injection molder or stamper will only bring better cost savings and long-term results to your project. Precision plates all of our finishes either overall or selectively using Micro-Plate (brush), Spot, Controlled Depth, Stripe and other proprietary select processes.

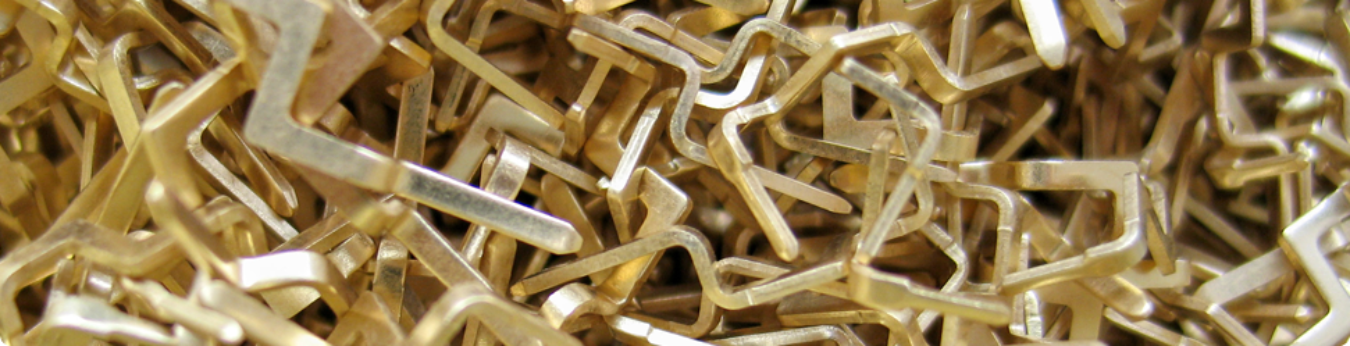

Barrel Plating: Looking for a cost-effective, repeatable and consistent loose piece barrel process? Precision ensures it by engineering every loose piece barrel project to the end specification. The goal of our calculated approach to loose piece barrel finishing, including all barrels and inspection plans, is to meet our clients' requirements cost effectively and reliably. Involving Precision in your design meetings can result in a competitive advantage for your company that helps you rise above the competition.

Rack Plating: All rack finishing is not created equal. Precision provides custom designed tooling to ensure that product damage is minimized, resulting in a consistently high quality product. This is an excellent way to plate etched sheets and small prototype orders to help you understand what the issues are and if the finish is right for your application.

In addition, Precision's product development support and service can help you prove that cost and quality requirements can be met before, during, or after your production cycle; allowing our experts to get involved early in the design and requirement specification process so that you can specify costs earlier and build a competitive advantage. Precision's engineering experts can create plated prototypes, either selectively or overall, in low or high volume to meet pre-production requirements.

For over 100 years, the people who work here at Precision have always placed an emphasis on service. People are what make the difference in our industry and we have over 900 years of experience under our roof. When you call Precision and hear our live operator, you will see that our attention to the personal touch and service is what we value most.